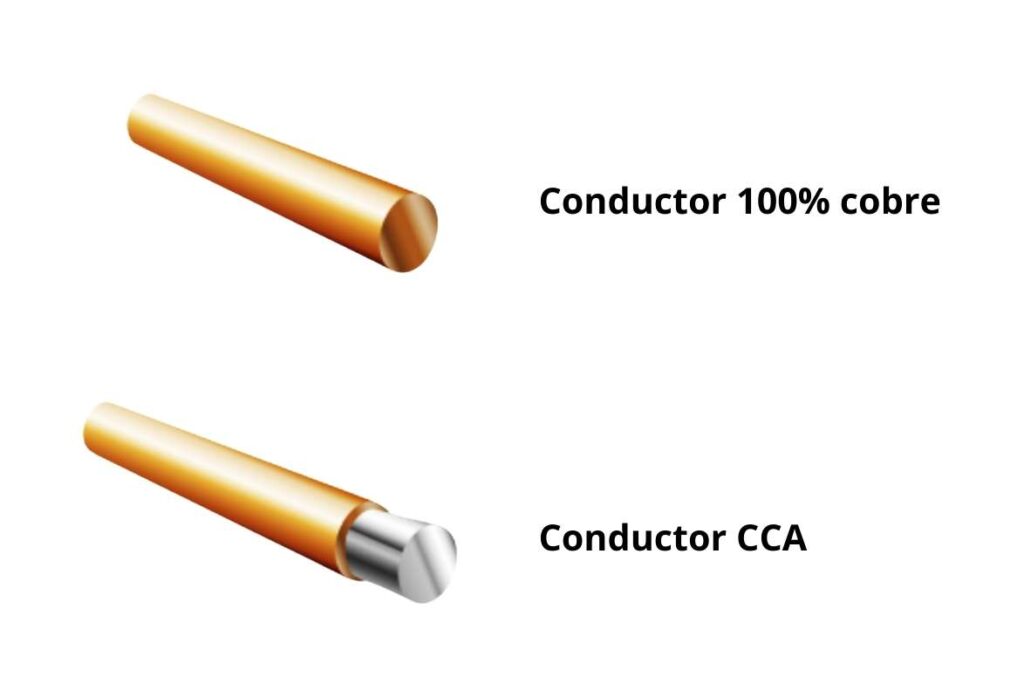

In the field of structured cabling, two main types of conductors are used: pure copper (Cu) cables and Copper Clad Aluminum (CCA) cables. Although visually they may appear similar, they have significant differences in performance, durability and safety.

Did I say “are used”? Yes, they are used, but I did not say that both types are allowed.

Let’s start with a brief comparison between pure copper cables and CCA cables to give you an idea of why they are not allowed or covered by local or international standards.

Pure copper cables

Pure copper cables are made entirely of copper, which gives them a high degree of resistance to corrosion:

- Excellent conductivity: Guarantees better data transmission.

- High mechanical resistance: Lower propensity to breakage.

- Durability: Does not rust over time.

- PoE (Power over Ethernet) compatibility: Ability to transmit power without risk of overheating.

CCA cables

CCA cables have an aluminum core covered by a thin layer of copper. Its main features include:

- Lower production cost: Aluminum is cheaper than copper.

- Low conductivity: Increased electrical resistance, voltage drops and lower performance in data transmission.

- Lower mechanical resistance: greater fragility and susceptibility to breakage.

- Accelerated oxidation: Faster deterioration of the connections.

- Incompatibility with PoE: Risk of overheating and possible fire.

With a first glance at their characteristics, we can already get an idea that the main incentive to commercialize CCA cables is their low cost, and this makes them attractive for projects with tight budgets. But do you really believe that the cost of the project is only based on the cost of the materials used?

We will explain in more detail what additional costs a project installed with CCA cable may face and why.

Importance of the use of copper cables in telecommunications

The use of copper cables is essential to ensure performance and safety in telecommunications infrastructures. According to Royal Decree 346/2011 and order ECE/983/2019 (commonly known as “Regulation for ICT”), cables must comply with EN-50288-6-1 and EN-50288-6-2, which implies the mandatory use of 100% copper conductors.

Moreover, there are several regulatory bodies of reference for telecommunications worldwide: ISO/IEC, CENELEC or ANSI/TIA. All of them indicate in their series of standards for structured cabling ISO11801, IEC 61156, EN 50288 and ANSI/TIA-568, the mandatory use of 100% copper conductors. Both for the permanent network sections and for the connection or patch cords.

Otherwise, the project may suffer disastrous consequences when using CCA cable:

- Low network performance: The lower conductivity of aluminum (Al) compared to copper (Cu) causes failures in data transmission. Technical certifications may not be passed, especially in tests at low transmission frequencies.

- Safety issues: The higher resistance of aluminum (Al) compared to copper (Cu) leads to a risk of overheating of conductors in PoE applications and a real fire hazard.

- Fragility: The lower flexibility and lower tenacity of aluminum (Al) compared to copper (Cu) makes CCA cables more prone to breakage and deterioration over time.

- Oxidation: Aluminum begins to oxidize as soon as it is exposed to air, typically when insulation displacement connections (IDC) are used to terminate the conductor. Contact performance in the oxidized area will deteriorate rapidly in CCA cables and cause breakage when subjected to vibration or movement.

- Limitations in transmission distance: While copper cables allow links up to 100 meters, CCA cables do not guarantee reliable performance over long distances due to their high attenuation.

- Recyclability: Copper is the most recycled metal in the world and part of its demand is covered through recycling, which is essential for sustainability. On the contrary, CCA cables do not allow the recyclability of the conductor as it is an extremely costly process to separate both Cu and Al elements. Extra investment in waste treatment is required at the time of dismantling the network.

- Fraud and lack of certifications: A CCA cable cannot be sold or certified as Cat6, Cat6A, Class FA, Class F, etc. since these classifications standardized by ISO11801, TIA/EIA-568 and EN50173 indicate that the conductor of the cable is 100% copper. The test performed by a cable certifier may give a correct result for a CCA cable, but the reason is because he does not analyze the material on which he checks the electrical parameters. Any laboratory or specialized technician knows that only 100% copper cables can be certified under these international standards, which specify both cable construction parameters and electrical parameters.

- Legal risks: the ICT Regulation (RD 346/2011 and Order ECE/983/2019) establishes that telecommunication networks must use copper conductors, using CCA in these environments is illegal and could have legal consequences for the cable supplier, installer and building developer.

And now that you’re probably wondering if you’ve messed up by not using 100% Cablelan (GTLAN) brand copper cable, how do you know if you need to flee the country or change your identity?

The first indication is the price of the material, a remarkably low offer may imply an aluminum core. If you have a multimeter you can measure the electrical resistance of the CCA cable, it will be about 40% higher than the resistance of a 100% copper cable.

Bending conductors to examine their mechanical behavior will also give you clues. While copper is fully malleable, aluminum, however, breaks easily.

Perhaps the simplest and most reliable test to differentiate a CCA cable from a pure copper cable is to use a nail file or fine grit sandpaper, file the surface of the conductor and observe what material makes up the core of the conductor. The copper layer in CCA cables is so thin that it can be removed with a simple scratch. If the color tone in the core remains homogeneous you can jump for joy, but if a silvery tone appears… Damn, I’ve got a CCA!

CE marking and its misinterpretation

It is a common misconception that if a product is CE marked it is suitable for use in any environment. The CE marking indicates that a product complies with minimum safety requirements for marketing in Europe.

However, the CE marking for twisted pair cables and patch cords does not certify the performance of a product in telecommunication networks. The CE marking for twisted pair telecommunication cables only guarantees that it is a cable that for safety reasons complies with certain fire performance characteristics. If your curiosity leads you to further information, you will see that this has nothing to do with the electrical performance of the cable or with the cable’s construction characteristics. These performance and characteristics are actually marked in the EN 50288, IEC 61156 and ISO/IEC 11801 standards, which do not fall under the umbrella of the CE marking.

Therefore, you can find CCA cables with CE marking. But that does not mean that they are specified for use in telecommunication networks.

Conclusion

| Feature | Copper Cable | CCA cable |

| Regulatory | Compliant with ISO11801, IEC 61156, EN 50288 and ANSI/TIA-568 | Not regulated |

| Conductivity | High, optimal for telecommunications | 64% less than copper |

| Flexibility and durability | High mechanical strength | Fragile and prone to breakage |

| Resistance to oxidation | Does not rust | Rapidly oxidizes |

| Recyclability | 100% recyclable | Non-recyclable |

| Maximum link distance | 100m | 60m |

| Use in PoE | Insurance | Risk of overheating and fire |

The use of pure copper cables is essential to ensure the quality and safety of telecommunications installations. Although CCA cables may appear to be an economical alternative, they have numerous shortcomings that affect their performance and can lead to problems. It is crucial that consumers and installers are aware of these differences and avoid decisions based on price alone. In addition, it is important to understand that CE marking does not certify compliance with telecommunications regulations and that certification to recognized standards is essential for a reliable network infrastructure.